There are numerous examples on Innovation in times of crisis with industry playing a major role. With Covid-19, universities have also turned up the Innovation Machine.

Some notable examples:

Columbia University: Innovation in face shield. Engineering researchers at Columbia in collaboration with Columbia University Irving Medical Center and New York-Presbyterian Hospital were able to produce close to 50,000 face shields/day. Initially producing thousands of these shields in the Engineering School’s Makerspace, the one-piece face shields are now being made by a contract manufacturer in Connecticut that can meet the demand. The die cut can be created for less than $1 per shield and made in seconds on the spot. At this point, 1.5 million are on order.

Working in the backyard of the hardest hit region in the country, Columbia has created the COVID Tech Innovation Group. In addition to shields, researchers are working on ventilators, HEPA filters, sample collection swabs, sterilization, PPEs, just to name a few areas.

Cal Berkeley: Sleep Apnea device into Ventilator. Researchers at the University of California, Berkley were able to turn an off-the-shelf continuous positive airway pressure (CPAP) sleep apnea machine to a fully functional ventilator. Like Columbia, the researchers used 3D printers to create parts. The new modifications allow the CPAP sleep apnea machine to accept oxygen where ambient air enters the device.

Since both the sleep apnea and parts used to modify the machines are FDA improved, researchers hope to deploy the machines quickly. In fact, the FDA recently issued

There are numerous examples on Innovation in times of crisis with industry playing a major role. With Covid-19, universities have also turned up the Innovation Machine.

Some notable examples:

Columbia University: Innovation in face shield. Engineering researchers at Columbia in collaboration with Columbia University Irving Medical Center and New York-Presbyterian Hospital were able to produce close to 50,000 face shields/day. Initially producing thousands of these shields in the Engineering School’s Makerspace, the one-piece face shields are now being made by a contract manufacturer in Connecticut that can meet the demand. The die cut can be created for less than $1 per shield and made in seconds on the spot. At this point, 1.5 million are on order.

Working in the backyard of the hardest hit region in the country, Columbia has created the COVID Tech Innovation Group. In addition to shields, researchers are working on ventilators, HEPA filters, sample collection swabs, sterilization, PPEs, just to name a few areas.

Cal Berkeley: Sleep Apnea device into Ventilator. Researchers at the University of California, Berkley were able to turn an off-the-shelf continuous positive airway pressure (CPAP) sleep apnea machine to a fully functional ventilator. Like Columbia, the researchers used 3D printers to create parts. The new modifications allow the CPAP sleep apnea machine to accept oxygen where ambient air enters the device.

Since both the sleep apnea and parts used to modify the machines are FDA improved, researchers hope to deploy the machines quickly. In fact, the FDA recently issued guidelines to allow sleep apnea machines to be used to support less critical, COVID-19 patients experiencing breathing problems.

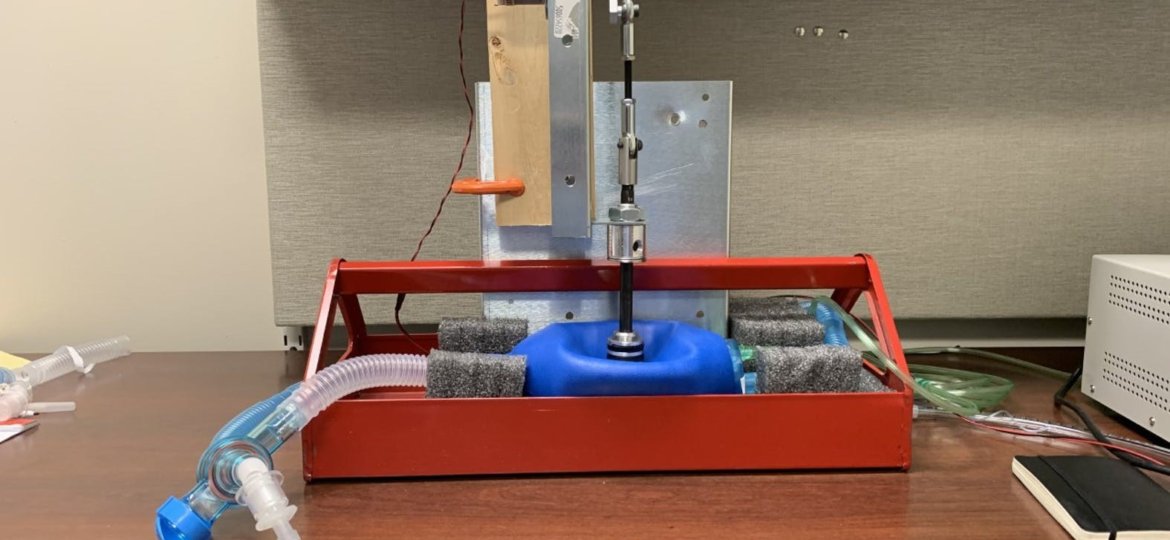

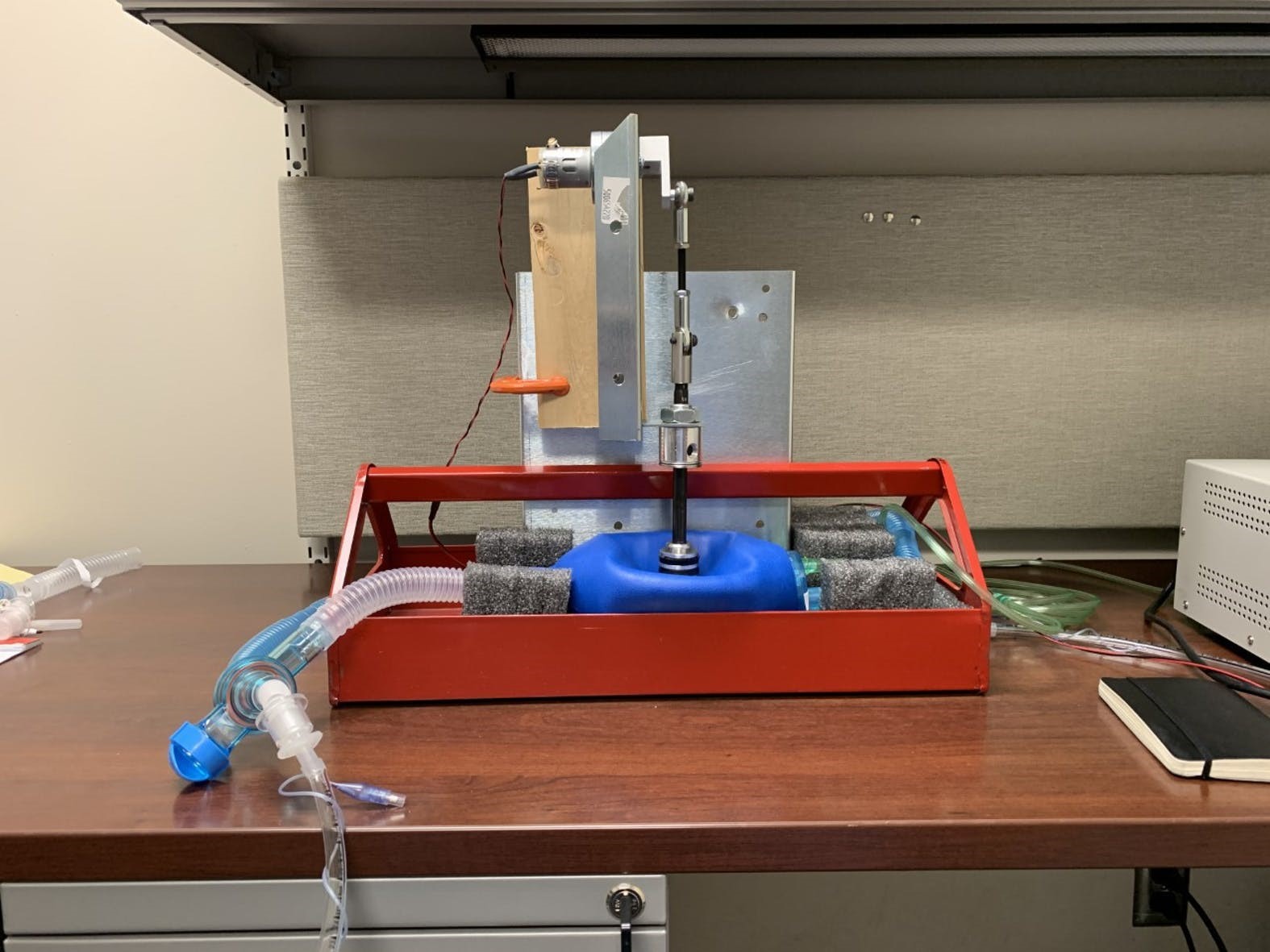

University of Minnesota: Innovation in Ventilators: When learning COVID-19 cases could consume all hospital ventilators, Dr. Stephen Richardson at the University of Minnesota searched parts in his medical device lab and built a homemade version. That included a red metal toolbox tray as its base and a motor ripped from another device. “We just went full-on MacGyver” stated Dr. Stephen Richardson. Costing a grand total of $150, an initial prototype kept a pig breathing for an hour. Could this budget ventilator be able to address a shortage?

These universities are not alone. Rice University, the University of Texas, the University of Illinois, and the University of Vermont have all been working on ventilators. Duke, Washington University among others have created face shields.

A recent webinar by the Association of University Technology Managers, with Tech Transfer Directors from Columbia, Duke, University of Minnesota, and Partners Healthcare indicated that innovation was driven in large part with outreach to industry, leveraging in part university and alumni contacts, and fostering collaboration with even amongst competing labs. Perhaps that last part can continue past the crisis?